Excel - Series: 40

To 1500°F (815 ºC) with optional materials

Design Standard

The PDC “Excel” series butterfly valve is available in sizes from 2″ thru 60″ in a combination of materials and optional features suitable for most mid-range differential pressures and a wide range of temperature conditions.

Specifications

To 1500°F (815 ºC) with optional materials

Design Features

- Inboard bushings of graphited bronze for long life, non-freezing, low torque characteristics on both shaft ends.

- Close tolerance machining for minimal leakage and dependable flow characteristics.

- Adjustable packing-Graphited TEFLON ® Braid. Valves can be repacked without removal from line on both shaft ends.

- Rugged mounting pads drilled and tapped for ease of installing actuating equipment and accessories.

- Flatted, keywayed or hexed ends on shafts are available to facilitate factory or field mounting of all types of actuating equipment. (Flatted shaft shown).

- Lightweight, solid ring, wafer design for ease of installation. Four holes to insure proper alignment without transfer of pipe stresses to the valve body.

Applications

- Blower Equipment

- Compressor Equipment

- Boiler Equipment

- Environmental Systems

- V.A.C

- Industrial Process Furnaces

- Oil Gas/Refining

- Power Generation/Co-Generation

- Water & Sewage

- Stationary Engines

- Chemical Equipment

- Mining Equipment

- Gas Recovery Systems

Standard Materials and Seat Construction

| 2″ – 14″ | 16″ – 24″ | 26″ – 60″ | |

|---|---|---|---|

| Body: | Cast Iron | Cast Iron | Cast Iron |

| Disc: | Cast Iron | Ductile Iron | Cast Iron |

| Shaft: | 416 Stainless Steel | 416 Stainless Steel | 416 Stainless Steel |

| Seat: | Swing-thru | Swing-thru | Swing-thru |

| Bushing: | Graphited Bronze | Graphited Bronze | Graphited Bronze |

| Packing: | Graphited Teflon Braid | Graphited Teflon Braid | Graphited Teflon Braid |

| Packing Nut: | Brass | Brass | Ductile Iron |

Optional Materials and Seat Construction

| Body: | High Temperature Iron, Carbon Steel, 316 Stainless Steel, 304 Stainless Steel |

| Disc: | High Temperature Iron, Carbon Steel, 316 Stainless Steel, 304 Stainless Steel |

| Shaft: | 316 Stainless Steel, 304 Stainless Steel, Incoloy, Monel |

| Seat: | Angle (2″-30″), Metal Step (2″-60″), Tadpole Step (8″- 60″) |

| Bushing: | 316 Stainless Steel, 304 Stainless Steel, Glass Filled Teflon, Metcar, Macor |

| Packing: | High Temperature Braid, Pure Teflon Braid, Teflon V-Ring, Spring Loaded |

| Packing Nut: | 316 Stainless Steel |

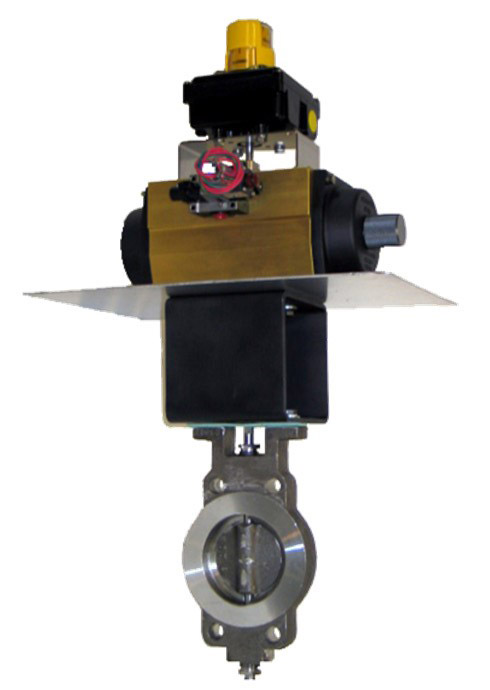

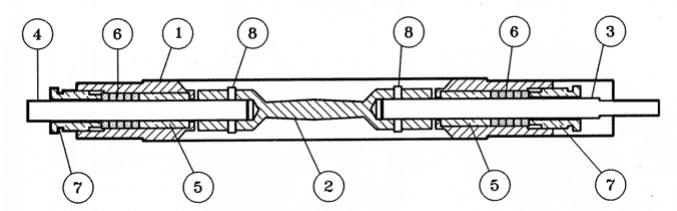

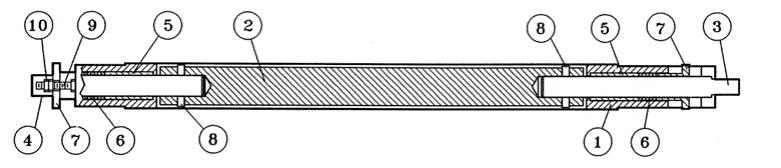

Excel Series 40— 2″ Through 14″ Valve

- Body

- Disc

- Power Shaft

- Idle Shaft

- Bushing

- Braided Packing

- Adjustable Packing Nut

- Shaft Retaining Pin

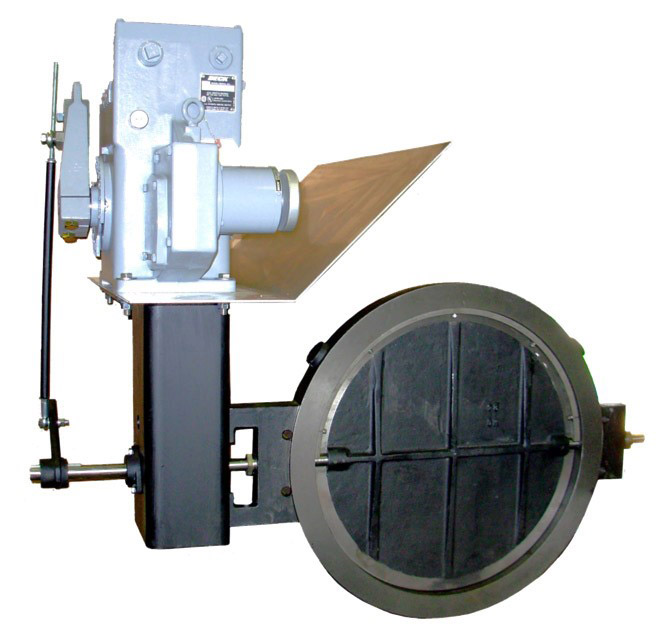

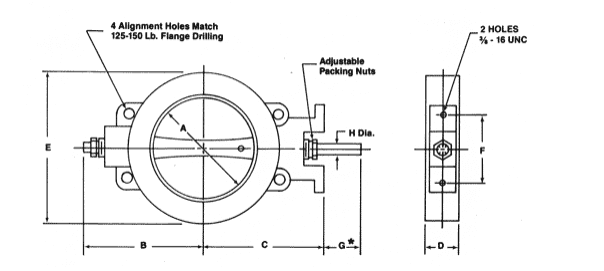

Excel Series 40– 16″ Through 24″ Valve

- Body

- Disc

- Power Shaft

- Idle Shaft

- Bushing

- Braided Packing

- Adjustable Packing Nut

- Shaft Retaining Pin

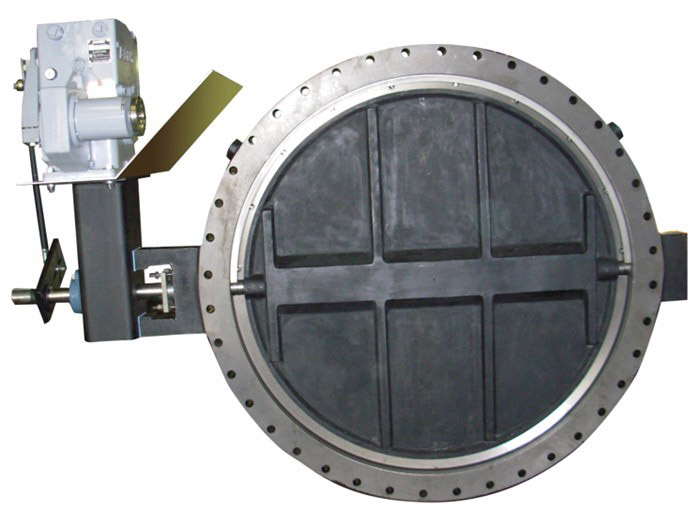

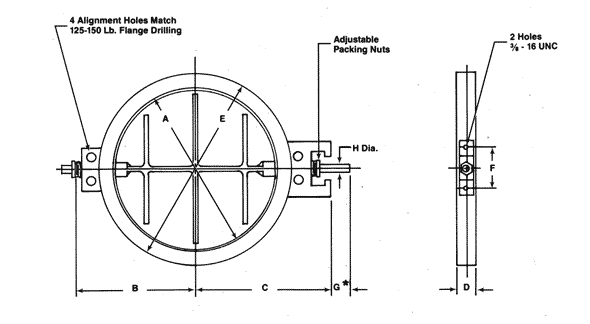

Excel Series 40—26″ Through 60″ Valve size

- Body

- Disc

- Power Shaft

- Idle Shaft

- Bushing

- Braided Packing

- Adjustable Packing Nut

- Shaft Retaining Pin

- Threaded Stud

- Hexed Jam Nut

Chart or Graph

*Torque, Lb-In, Required for PDC Swing Thru Butterfly Valves with Disc in Closed Position for Temperatures up to 450° Fahrenheit

*Below torques only apply to normal clean service conditions.

| VALVE SIZE | PRESSURE DROP ACROSS DISC IN CLOSED POSITION, PSI | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.5 | 1 | 5 | 10 | 15 | 20 | 25 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | 125 | 150 | |

| 2 | 50 | 50 | 52 | 53 | 55 | 56 | 58 | 59 | 62 | 65 | 68 | 71 | 74 | 77 | 80 | 88 | 95 |

| 2.5 | 50 | 51 | 53 | 55 | 58 | 60 | 63 | 65 | 70 | 75 | 80 | 85 | 90 | 95 | 100 | 113 | 125 |

| 3 | 50 | 51 | 54 | 57 | 61 | 64 | 68 | 71 | 78 | 85 | 92 | 99 | 108 | 113 | 120 | 138 | 155 |

| 4 | 51 | 52 | 59 | 67 | 78 | 84 | 93 | 101 | 118 | 135 | 152 | 169 | 188 | 203 | 220 | 263 | – |

| 5 | 51 | 53 | 63 | 75 | 88 | 100 | 113 | 125 | 150 | 175 | 200 | 225 | 250 | 275 | 300 | – | – |

| 6 | 52 | 54 | 69 | 88 | 107 | 126 | 145 | 164 | 202 | 240 | 278 | 316 | 354 | – | – | – | – |

| VALVE SIZE | PRESSURE DROP ACROSS DISC IN CLOSED POSITION, PSI | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.5 | 1 | 3 | 5 | 8 | 10 | 13 | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | 60 | 70 | |

| 8 | 124 | 128 | 158 | 195 | 233 | 270 | 308 | 345 | 420 | 495 | 570 | 645 | 720 | 795 | – | – | – |

| 10 | 129 | 137 | 171 | 205 | 256 | 290 | 341 | 375 | 460 | 545 | 630 | 715 | 800 | 885 | 970 | 1140 | 1310 |

| 12 | 132 | 143 | 189 | 235 | 304 | 350 | 419 | 465 | 580 | 695 | 810 | 925 | 1040 | 1155 | 1270 | – | – |

| 14 | 139 | 157 | 231 | 305 | 416 | 490 | 601 | 675 | 860 | 1045 | 1230 | – | – | – | – | – | – |

| VALVE SIZE | PRESSURE DROP ACROSS DISC IN CLOSED POSITION, PSI | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.5 | 1 | 2 | 4 | 5 | 7 | 9 | 10 | 12 | 14 | 15 | 17 | 19 | 20 | 22 | 24 | 25 | |

| 16 | 223 | 245 | 335 | 425 | 560 | 650 | 785 | 875 | 1100 | 1325 | 1550 | 1775 | 2000 | – | – | – | – |

| 18 | 235 | 270 | 410 | 550 | 760 | 900 | 1100 | 1250 | 1600 | 1950 | 2300 | 2650 | – | – | – | – | – |

| 20 | 245 | 290 | 380 | 580 | 650 | 830 | 1010 | 1100 | 1280 | 1460 | 1550 | 1730 | 1910 | 2000 | 2180 | 2380 | 2450 |

| 22 | 261 | 322 | 444 | 688 | 810 | 1054 | 1298 | 1420 | 1664 | 1908 | 2030 | 2274 | 2518 | 2640 | – | – | – |

| 24 | 280 | 359 | 518 | 836 | 995 | 1313 | 1631 | 1790 | 2108 | 2426 | 2585 | 2903 | – | – | – | – | – |

| VALVE SIZE | PRESSURE DROP ACROSS DISC IN CLOSED POSITION, PSI | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.5 | 1.2 | 2 | 2.5 | 3 | 3.5 | 4 | 4.5 | 5 | 5.5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | |

| 26 | 403 | 505 | 710 | 1120 | 1325 | 1735 | 2145 | 2350 | 2760 | 3170 | – | – | – | – | – | – | – |

| 28 | 429 | 687 | 816 | 945 | 1074 | 1203 | 1332 | 1461 | 1590 | 1719 | 1848 | 2106 | 2364 | 2622 | 2880 | 3138 | 3396 |

| 30 | 460 | 779 | 938 | 1098 | 1257 | 1417 | 1576 | 1738 | 1695 | 2055 | 2214 | 2533 | 2652 | 3171 | 3490 | 3809 | – |

| 32 | 592 | 976 | 1168 | 1380 | 1552 | 1744 | 1936 | 2128 | 2320 | 2512 | 2704 | 3088 | 3472 | 3856 | 4240 | 4624 | 5008 |

| 34 | 632 | 1096 | 1328 | 1560 | 1792 | 2024 | 2256 | 2488 | 2720 | 2952 | 3184 | 3648 | 4112 | 4576 | 5040 | – | – |

| 36 | 677 | 1231 | 1508 | 1785 | 2062 | 2339 | 2616 | 2693 | 3170 | 3447 | 3724 | 4278 | 4832 | 5396 | – | – | – |

| 38 | 727 | 1381 | 1708 | 2035 | 2362 | 2689 | 3016 | 3343 | 3670 | 3997 | 4324 | 4978 | 5832 | – | – | – | – |

| 40 | 883 | 1648 | 2030 | 2413 | 2795 | 3178 | 3560 | 3943 | 4325 | 4708 | 5090 | 5855 | 6620 | 7385 | – | – | – |

| 42 | 945 | 1834 | 2278 | 2723 | 3167 | 3612 | 4058 | 4501 | 4945 | 5390 | 5834 | 6723 | 7612 | – | – | – | – |

| 44 | 1013 | 2039 | 2552 | 3065 | 3578 | 4091 | 4804 | 5117 | 5630 | 6143 | 6656 | 7882 | – | – | – | – | – |

| 46 | 1088 | 2264 | 2852 | 3440 | 4028 | 4616 | 5204 | 5792 | 6380 | 6968 | 7586 | – | – | – | – | – | – |

| 48 | 1170 | 2510 | 3180 | 3850 | 4520 | 5190 | 5860 | 6530 | 7200 | – | – | – | – | – | – | – | – |

| 54 | 1510 | 3029 | 3788 | 4548 | 5307 | 6067 | 6826 | 7586 | 8345 | – | – | – | – | – | – | – | – |

| 60 | 1856 | 3588 | 4424 | 5280 | 6136 | 6992 | 7848 | 9560 | – | – | — | – | – | – | – | – | – |

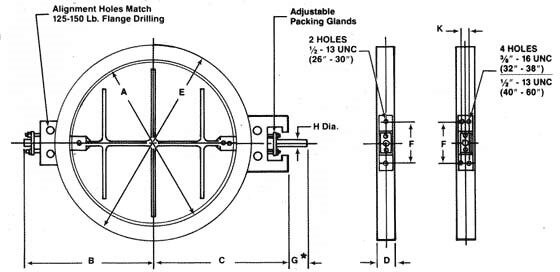

Typical Dimensions: 2″ thru 14″

| Size (inch) | A | B | C | D | E | F | H | Max. ΔP | Approx. Wt. (Lbs) |

|---|---|---|---|---|---|---|---|---|---|

| 2 | 2 | 5-3/8 | 5-3/8 | 1-1/2 | 3-7/8 | 4-1/4 | 1/2 | 150 | 9 |

| 2-1/2 | 2-1/2 | 5-5/8 | 5-5/8 | 1-1/2 | 4-5/8 | 4-1/4 | 1/2 | 150 | 10 |

| 3 | 3 | 5-7/8 | 5-7/8 | 1-1/2 | 5-5/8 | 4-1/4 | 1/2 | 150 | 11 |

| 4 | 4 | 6-3/8 | 6-3/8 | 1-1/2 | 6-3/8 | 4-1/4 | 1/2 | 125 | 12 |

| 5 | 5 | 6-7/8 | 6-7/8 | 1-1/2 | 7-1/2 | 4-1/4 | 1/2 | 100 | 15 |

| 6 | 6 | 7-3/8 | 7-3/8 | 1-1/2 | 8-1/2 | 4-1/4 | 1/2 | 80 | 17 |

| 8 | 8 | 9-5/8 | 9-5/8 | 1-7/8 | 10-3/4 | 5-1/8 | 3/4 | 90 | 32 |

| 10 | 10 | 10-5/8 | 10-5/8 | 1-7/8 | 13 | 5-1/8 | 3/4 | 70 | 40 |

| 12 | 12 | 11-5/8 | 11-5/8 | 1-7/8 | 15-1/4 | 5-1/8 | 3/4 | 50 | 50 |

| 14 | 13-1/8 | 12-1/8 | 12-1/8 | 1-7/8 | 16-3/8 | 5-1/8 | 3/4 | 30 | 70 |

Typical Dimensions: 16″ thru 24″

| Size (inch) | A | B | C | D | E | F | H | Max. ΔP | Approx. Wt. (Lbs) |

|---|---|---|---|---|---|---|---|---|---|

| 16 | 15-1/8 | 14-1/2 | 14-1/2 | 2-3/8 | 18-1/4 | 5-1/8 | 1 | 40 | 122 |

| 18 | 17-1/8 | 15-1/2 | 15-1/2 | 2-3/8 | 20-3/4 | 5-1/8 | 1 | 30 | 155 |

| 20 | 19-1/8 | 16-1/2 | 16-1/2 | 2-3/8 | 22-3/4 | 5-1/8 | 1 | 25 | 192 |

| 22 | 21-1/8 | 17-1/2 | 17-1/2 | 2-3/8 | 25 | 5-1/8 | 1 | 20 | 232 |

| 24 | 23-1/8 | 18-1/2 | 18-1/2 | 2-3/8 | 27 | 5-1/8 | 1 | 17 | 276 |

Typical Dimensions: 26″ thru 60″

Alignment holes shown match ANSI 125/150 lb. flange bolt circle and number of holes. On valves 32″ and larger, the diameter of the holes adjacent the shaft on both ends, match ANSI 25/AWWA C207B.

| Size (inch) | A | B | C | D | E | F | H | Max. ΔP | Approx. Wt.(Lbs) | |

|---|---|---|---|---|---|---|---|---|---|---|

| 26 | 25-1/8 | 21 | 21 | 2-3/4 | 29 | 5-1/8 | 1-1/4 | – | 14 | 324 |

| 28 | 27-1/8 | 22 | 22 | 2-3/4 | 31 | 5-1/8 | 1-1/4 | – | 12 | 376 |

| 30 | 29-1/8 | 23 | 23 | 2-3/4 | 33-1/2 | 5-1/8 | 1-1/4 | – | 11 | 432 |

| 32 | 31 | 25 | 25 | 3-1/4 | 35-1/2 | 7 | 1-1/2 | 1-3/8 | 12 | 512 |

| 34 | 33 | 26 | 26 | 3-1/4 | 37-1/2 | 7 | 1-1/2 | 1-3/8 | 10 | 578 |

| 36 | 35 | 27 | 27 | 3-1/4 | 40 | 7 | 1-1/2 | 1-3/8 | 9 | 648 |

| 38 | 37 | 28 | 28 | 3-1/4 | 42-3/4 | 7 | 1-1/2 | 1-3/8 | 8 | 722 |

| 40 | 39 | 30-1/4 | 30-1/4 | 4 | 44-3/4 | 7 | 1-3/4 | 2 | 9 | 888 |

| 42 | 41 | 31-1/4 | 31-1/4 | 4 | 46-3/4 | 7 | 1-3/4 | 2 | 8 | 970 |

| 44 | 43 | 32-1/4 | 32-1/4 | 4 | 49-1/2 | 7 | 1-3/4 | 2 | 7 | 970 |

| 46 | 45 | 33-1/4 | 33-1/4 | 4 | 51-1/2 | 7 | 1-3/4 | 2 | 6 | 1163 |

| 48 | 47 | 34-1/4 | 34-1/4 | 4 | 53-3/4 | 7 | 1-3/4 | 2 | 5 | 1267 |

| 54 | 53 | 37 | 37 | 6 | 60-1/4 | 10 | 2 | 2 | 5 | 1840 |

| 60 | 59 | 40 | 40 | 7 | 66-3/4 | 10 | 2-1/4 | 2-1/2 | 5 | 2600 |

* “G” Length and configuration of the shaft end will vary to accommodate specific actuators. Refer to the accessory section for typical flatted, keywayed, and hexed end configurations available.

MAX. ∆P is based on 0° disc position, using standard materials of construction at a maximum temperature of 450° Fahrenheit.

Consult factory for MAX. ∆P for elevated temperatures.

Cv Values for PDC Swing Thru Butterfly Valves

By definition, Cv is the flow coefficient of a control device or flow restriction. Cv is defined as the number of US gallons of 60°F water per minute which will flow through the given restriction with a one pound per square inch pressure drop.

Cv Values

(Flow in GPM of 60°F water at 1 psi pressure drop, specific gravity=1)

| Valve size | Disc Angle, Degrees | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 10° | 20° | 30° | 40° | 50° | 60° | 70° | 80° | 90° | |

| 2 | 2 | 5 | 11 | 20 | 34 | 49 | 64 | 83 | 90 |

| 2-1/2 | 4 | 8 | 20 | 34 | 56 | 84 | 126 | 178 | 194 |

| 3 | 6 | 14 | 30 | 51 | 85 | 132 | 202 | 279 | 370 |

| 4 | 13 | 28 | 54 | 98 | 159 | 257 | 391 | 550 | 747 |

| 5 | 21 | 43 | 88 | 158 | 265 | 429 | 636 | 913 | 1272 |

| 6 | 30 | 63 | 126 | 228 | 382 | 632 | 955 | 1370 | 1999 |

| 8 | 53 | 111 | 225 | 406 | 680 | 1125 | 1698 | 2591 | 3853 |

| 10 | 83 | 174 | 351 | 635 | 1063 | 1759 | 2655 | 4052 | 6361 |

| 12 | 120 | 252 | 506 | 914 | 1531 | 2533 | 3826 | 5835 | 9164 |

| 14 | 143 | 302 | 606 | 1096 | 1835 | 3035 | 4584 | 6992 | 10981 |

| 16 | 191 | 400 | 805 | 1455 | 2436 | 4118 | 6388 | 9835 | 12266 |

| 18 | 244 | 513 | 1032 | 1865 | 3123 | 5279 | 8185 | 12608 | 15725 |

| 20 | 305 | 640 | 1287 | 2326 | 3896 | 6584 | 10209 | 15725 | 19612 |

| 22 | 372 | 781 | 1570 | 2838 | 4753 | 8033 | 12456 | 19186 | 23929 |

| 24 | 445 | 936 | 1882 | 3401 | 5696 | 9626 | 14926 | 22990 | 28674 |

| 26 | 526 | 1105 | 2221 | 4015 | 6723 | 11364 | 17619 | 27139 | 33848 |

| 28 | 613 | 1288 | 2589 | 4679 | 7836 | 13245 | 20536 | 31632 | 39451 |

| 30 | 706 | 1485 | 2985 | 5395 | 9035 | 15270 | 23676 | 36468 | 45484 |

| 32 | 800 | 1682 | 3382 | 6112 | 10235 | 17299 | 26823 | 41315 | 51528 |

| 34 | 907 | 1906 | 3832 | 6926 | 11599 | 19603 | 30395 | 46817 | 58392 |

| 36 | 1020 | 2144 | 4311 | 7791 | 13047 | 22052 | 34191 | 52664 | 65684 |

| 38 | 1140 | 2396 | 4818 | 8707 | 14581 | 24644 | 38211 | 58855 | 73405 |

| 40 | 1267 | 2662 | 5352 | 9674 | 16200 | 27380 | 42453 | 65390 | 81555 |

| 42 | 1400 | 2942 | 5915 | 10691 | 17904 | 30260 | 46919 | 72268 | 90134 |

| 44 | 1540 | 3236 | 6507 | 11760 | 19693 | 33284 | 51608 | 79491 | 99143 |

| 46 | 1687 | 3544 | 7126 | 12879 | 21568 | 36453 | 56520 | 87057 | 108580 |

| 48 | 1840 | 3866 | 7774 | 14049 | 23527 | 39765 | 61656 | 94968 | 118446 |

| 54 | 2340 | 4916 | 9885 | 17865 | 29910 | 50566 | 78403 | 120762 | 150617 |

| 60 | 2899 | 6093 | 12250 | 22139 | 37065 | 62663 | 97159 | 149653 | 186650 |