High-Performance

Size: 1-1/2" to 36" (Larger size available on request)

Operating Temperature: -25 °C to 180 °C (Soft Seating)

-25 °C to 600 °C (Metal to Metal Seating)

-25 °C to 600 °C (Metal to Metal Seating)

Pressure Rating: ANSI 150 Class

ANSI 300/600 Class

ANSI 300/600 Class

Design Standard

High-Performance butterfly valves for bi-directional* shut-off and modulating service for standard industrial process lines. Materials of construction options include Carbon Steel, Stainless steel, Duplex Grade Steel, and high-quality custom materials for desired applications.

Specifications

Size Range:

1-1/2" to 36" (Larger size available on request)

Temperature:

-25 °C to 180 °C (Soft Seating)

-25 °C to 600 °C (Metal to Metal Seating)

-25 °C to 600 °C (Metal to Metal Seating)

Pressure Rating:

ANSI 150 Class, ANSI 300/600 Class

Body Style:

WCB/CF8/CF8M

Face to Face:

API 609 Catagory B/ANSI B16.10 (40 to 600 NB)

ISO 5752 Series 20

MSS SP-68 (650 to 1200 NB)

ISO 5752 Series 20

MSS SP-68 (650 to 1200 NB)

Body Material:

WCB/CF8/CF8M

Stem Material:

AISI 410/304/316

Disc Material:

CF8/CF8M

Disc Style:

Spherical Disc valve

Seat:

PTFE (available EPDM/Metal to Metal)

End Connection:

Wafer

Lug type

Lug type

Operating:

Hand lever

Worm Gear Box

Worm Gear Box

Design and Manufacturing:

API 609 Catagory B (40 to 600 NB)

MSS SP-68 (650 to 1200 NB)

MSS SP-68 (650 to 1200 NB)

Inspection and Testing:

API 598/ANSI FCI 70-2 (40 to 600 NB)

API 598/BS 6755 (650 to 1200 NB)

API 598/BS 6755 (650 to 1200 NB)

Flange Standard Conformity:

ANSI B16.5 Class 150

ASME/ANSI B 16.47 Series 'A'

ASME/ANSI B 16.47 Series 'A'

Shaft:

AISI 410/304/316

Construction Type:

Double Eccentric Disc Design

Plate Mounting:

Namur Standard

Operating Temp. Range:

-25 degC to 180 DegC(Soft Seating)

-25 degC to 600 DegC(Metal to Metal Seating)

-25 degC to 600 DegC(Metal to Metal Seating)

Fire Safe Testing:

API 607

Pressure Temperature Rating:

ASME/ANSI B16.34

Design Features

- Compact Design – Full Port – Offers Mass Flow

- Simple Structure, Light & Smooth – Takes very short time for Opening & Closing with very Low Torque

- Easy Maintenance – Replaceable Seals Design

- Self-Sealing – Self Cleaning the under-cut Disc Segment and seal tends to wipe away the material form the sealing area

- Gland Pressing Plate – ensure compete utilization of gland seals

- Wafer and Lug styles available in ANSI 300 & ANSI 600

- Spherical Disc Valve has been Proved as Superior to Other Valves

- Space

- Pressure Range

- Multiple Operations

- Weight

- Top mounting flange matches ISO 5211

Applications

- Hygienic Powder & Slurries, especially in Pharmaceutical Industries

- Chemical and Dyeing Fluids in Textile Processing Brine Waters & Oils

- Steam Lines, Air/ Gas Lines/ Vacuum

Chart or Graph

| CV Value in GPM | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| VALVE SIZE | CV Full Open 90° | Differential Pressure (ΔP) | |||||||

| MM | Inch | (GPM)Class 150 | 5 Kg/cm2 | 10 Kg/cm2 | 15 Kg/cm2 | 20 Kg/cm2 | |||

| 40 | 1-1/2″ | 70 | 0.8 | 1 | 1.2 | 1.5 | |||

| 50 | 2″ | 92 | 0.9 | 1.2 | 1.5 | 1.7 | |||

| 65 | 2-1/2″ | 150 | 1.6 | 2.2 | 2.4 | 3 | |||

| 80 | 3″ | 260 | 3 | 3.4 | 4.2 | 5 | |||

| 100 | 4″ | 460 | 4 | 4.6 | 5.4 | 6.4 | |||

| 125 | 5″ | 760 | 5.8 | 8 | 9.5 | 11.5 | |||

| 150 | 6″ | 1350 | 9 | 11.5 | 12.5 | 14.5 | |||

| 200 | 8″ | 2200 | 14 | 17.5 | 24 | 28 | |||

| 250 | 10″ | 3200 | 23.5 | 26.5 | 28 | 30 | |||

| 300 | 12″ | 4700 | 32 | 36 | 40 | 50 | |||

| 350 | 14″ | 5800 | 50 | 65 | 83.5 | 108.5 | |||

| 400 | 16″ | 8000 | 69.4 | 94.5 | 120 | 160 | |||

| 450 | 18″ | 10500 | 95.5 | 128 | 157.2 | 205 | |||

| 500 | 20″ | 14000 | 122.5 | 193.3 | 210 | 293.4 | |||

| 600 | 24″ | 21000 | 213.3 | 293.4 | 366.7 | 440.1 | |||

| 650 | 26″ | 23400 | 265 | 350 | 400 | 510 | |||

| 700 | 28″ | 27000 | 300 | 395 | 480 | 595 | |||

| 750 | 30″ | 33300 | 321 | 420 | 519 | 617 | |||

| 800 | 32″ | 40200 | 481 | 630 | 780 | 920 | |||

| 900 | 36″ | 56500 | 518 | 663 | 850 | 992 | |||

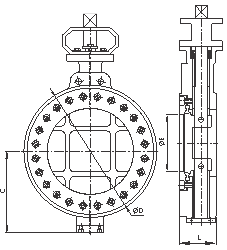

| All Dimensions are in mm | All Dimensions are in Inch | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| VALVE SIZE | L | C | ØE | ØD | L | C | ØE | ØD | ||

| MM | Inch | |||||||||

| 40 | 1-1/2″ | 42 | 57 | 38 | 82 | 1.68 | 2.28 | 1.52 | 3.28 | |

| 50 | 2″ | 45 | 68.5 | 50.8 | 95 | 1.8 | 2.74 | 2.032 | 3.8 | |

| 65 | 2-1/2″ | 48 | 74.5 | 60.6 | 108 | 1.92 | 2.98 | 2.424 | 4.32 | |

| 80 | 3″ | 48 | 80 | 72 | 127 | 1.92 | 3.2 | 2.88 | 5.08 | |

| 100 | 4″ | 54 | 96 | 100 | 159 | 2.16 | 3.84 | 4 | 6.36 | |

| 125 | 5″ | 57 | 117 | 123 | 186 | 2.28 | 4.68 | 4.92 | 7.44 | |

| 150 | 6″ | 57 | 132 | 143 | 217 | 2.28 | 5.28 | 5.72 | 8.68 | |

| 200 | 8″ | 64 | 157 | 192 | 270 | 2.56 | 6.28 | 7.68 | 10.8 | |

| 250 | 10″ | 72 | 187 | 239 | 322 | 2.88 | 7.48 | 9.56 | 12.88 | |

| 300 | 12″ | 82 | 218 | 290 | 382 | 3.28 | 8.72 | 11.6 | 15.28 | |

| 350 | 14″ | 92 | 242 | 335 | 436 | 3.68 | 9.68 | 13.4 | 17.44 | |

| 400 | 16″ | 102 | 270.5 | 387.5 | 495 | 4.08 | 10.82 | 15.5 | 19.8 | |

| 450 | 18″ | 114 | 362 | 425 | 540 | 4.56 | 14.48 | 17 | 21.6 | |

| 500 | 20″ | 127 | 400 | 475 | 595 | 5.08 | 16 | 19 | 23.8 | |

| 600 | 24″ | 154 | 454 | 560 | 705 | 6.16 | 18.16 | 22.4 | 28.2 | |

| 650 | 26″ | 165 | 478 | 608 | 755 | 6.6 | 19.12 | 24.32 | 30.2 | |

| 700 | 28″ | 165 | 505 | 661.5 | 810 | 6.6 | 20.2 | 26.46 | 32.4 | |

| 750 | 30″ | 190 | 542 | 596 | 855 | 7.6 | 21.68 | 23.84 | 34.2 | |

| 800 | 32″ | 190 | 580 | 755 | 913 | 7.6 | 23.2 | 30.2 | 36.52 | |

| 900 | 36″ | 203 | 640 | 864 | 1032 | 8.12 | 25.6 | 34.56 | 41.28 | |