Triple Offset

Design Standard

The “Triple Offset” butterfly valve is available in a variety of both ANSI and PN classes, sizes and configurations.

Triple Offset Butterfly Valves are suitable for both throttling and positive isolation applications. These valves can control bidirectional flow, have zero leakage, low fugitive emissions, and work in steam-based applications up to 1022° F (550° C).

The triple offset sealing system allows the disc to move smoothly and frictionless along the specially designed body seat & disc seal. When the disc is closed, the seal ring (on the disc) energizes the seat (on the body), providing a snug-tight, high-performance fit. The laminated seal is constructed with grafoil layers sandwiched between metal laminations. This resiliency of the seal flexes and energizes according to the compressive forces generated and allows for minor body deformations due to temperature fluctuations without the risk of jamming. This provides a uniform “snap-in” effect and ensures bubble-tight shut-off.

Specifications

Lug type (3" to 24")

Flanged (3" to 24")

Design Features

- Metal to metal sealing

- Triple offset for quarter-turn design

- Torque seated

- More torque = More tightness

- Bi-directional tight shutoff

- Zero leakage compared to API 598

- Speed of Operation: Variable closing speed as required

- Non-rubbing rotation seating

- No jamming

- No cavities

- Space & Weight saving compared to gate valves and ball valves

- Inherently fire safe and fire tested

- Less maintenance

- Control capability

Applications

- Process fluids

- Hydrocarbons

- Steam/Geothermal steam

- Hot gas/Sour gas (NACE)

- Blow down

- Sulfur recovery

- Acid, Caustic, Chloride

- Abrasive service

Chart or Graph

| VALVE TORQUE 150# | ||||

|---|---|---|---|---|

| VALVE SIZE | 5 Bar | 10 Bar | 20 Bar | |

| MM | Inch | N-m | N-m | N-m |

| 50 | 2″ | 11 | 15 | 21 |

| 65 | 2-1/2″ | 20 | 28 | 38 |

| 80 | 3″ | 38 | 43 | 63 |

| 100 | 4″ | 50 | 58 | 80 |

| 125 | 5″ | 73 | 100 | 144 |

| 150 | 6″ | 113 | 144 | 181 |

| 200 | 8″ | 175 | 219 | 350 |

| 250 | 10″ | 294 | 331 | 375 |

| 300 | 12″ | 400 | 450 | 625 |

| CV Values | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| VALVE SIZE | 10° | 20° | 30° | 40° | 50° | 60° | 70° | 80° | 90° | |

| MM | Inch | |||||||||

| 50 | 2″ | 2 | 5 | 11 | 19 | 28 | 41 | 58 | 77 | 85 |

| 65 | 2-1/2″ | 2 | 9 | 20 | 28 | 45 | 60 | 80 | 120 | 130 |

| 80 | 3″ | 3 | 10 | 22 | 42 | 64 | 96 | 150 | 157 | 160 |

| 100 | 4″ | 6 | 17 | 41 | 75 | 116 | 174 | 273 | 284 | 290 |

| 125 | 5″ | 6 | 45 | 75 | 170 | 280 | 478 | 650 | 707 | 795 |

| 150 | 6″ | 7 | 51 | 119 | 221 | 340 | 510 | 799 | 833 | 850 |

| 200 | 8″ | 4 | 103 | 239 | 445 | 684 | 1026 | 1607 | 1676 | 1710 |

| 250 | 10″ | 50 | 151 | 353 | 655 | 1008 | 1515 | 2369 | 2470 | 2520 |

| 300 | 12″ | 79 | 236 | 552 | 1024 | 1576 | 2364 | 3704 | 3861 | 3940 |

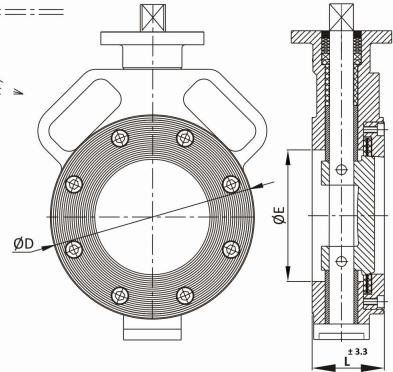

| Dimensions are in mm | ||||

|---|---|---|---|---|

| VALVE SIZE | L | ØE | ØD | |

| MM | Inch | |||

| 50 | 2″ | 47 | 50.8 | 95 |

| 65 | 2-1/2″ | 52 | 61.6 | 108 |

| 80 | 3″ | 52 | 72 | 127 |

| 100 | 4″ | 57 | 100 | 159 |

| 125 | 5″ | 60 | 123 | 186 |

| 150 | 6″ | 60 | 143 | 217 |

| 200 | 8″ | 67 | 192 | 270 |

| 250 | 10″ | 72 | 239 | 322 |

| 300 | 12″ | 75 | 290 | 382 |

| Dimensions are in inch | ||||

|---|---|---|---|---|

| VALVE SIZE | L | ØE | ØD | |

| MM | Inch | |||

| 50 | 2″ | 1.88 | 2.032 | 3.8 |

| 65 | 2-1/2″ | 2.08 | 2.464 | 4.32 |

| 80 | 3″ | 2.08 | 2.88 | 5.08 |

| 100 | 4″ | 2.28 | 4 | 6.36 |

| 125 | 5″ | 2.4 | 4.92 | 7.44 |

| 150 | 6″ | 2.4 | 5.72 | 8.68 |

| 200 | 8″ | 2.68 | 7.68 | 10.8 |

| 250 | 10″ | 2.68 | 9.56 | 12.88 |

| 300 | 12″ | 3 | 11.6 | 15.28 |